Unity in Action: MP Shockat Adam Connects with Leicester’s Learners and Manufacturers

20-10-2025

Friday 17th October marked a truly special day in Leicester – a day that celebrated skills, community, and the unshakeable resilience of UK manufacturing.

The Fashion Technology Academy (FTA) in Leicester held an inspiring certificate presentation for Level 1 – 3 stitching learners. Learners arrived dressed in their finest, proud of the journey they had undertaken. Shockat Adam MP, Independent Member for Leicester South, was there to present the certificates. More than just a formality, he took time to listen deeply, encourage genuinely, and most memorably, urge learners to focus on improving “one stitch at a time” a phrase that resonated deeply with everyone in the room.

Jenny Holloway CEO of FEL / FTA stated: “These learners are proud. They want to work.”

The celebration, as always, was heartfelt, learners, many facing financial hardship, brought in homemade dishes, sharing a warm, humble lunch with staff and guests. It was a quiet reminder of the kindness and community at the heart of Leicester’s workforce.

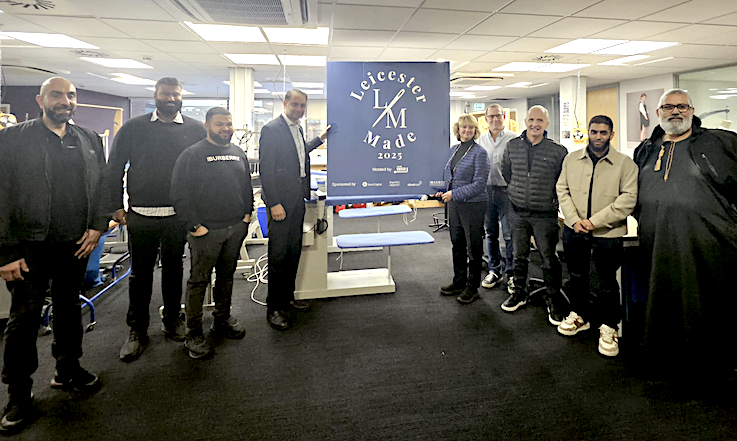

Shockat Adam MP, additionally took part in the Apparel & Textile Manufacturers Federation (ATMF) meeting. Attended by leading factory owners, FTA leaders, the meeting focused on the future of UK manufacturing and why Leicester remains at its core.

The message was clear: Leicester has the skills, the will, the speed, and the capacity but it needs commitment, orders, and a level playing field.

Key Discussion Highlights:

- Manufacturing capacity is strong, with factory order turnaround times of just 2 weeks (200–4,000 units per style).

- Skills are not the issue hundreds of learners are being trained in real-world settings, and they’re ready to work.

- What’s missing? Orders. Consistent contracts. Retail engagement.

Despite the proven efficiency of local production, major retailers like Next and Marks & Spencer continue to source offshore.

“Why don’t these brands support Made in Leicester? It’s profitable, ethical, and efficient.”

A major point of discussion was the £400 billion public procurement budget, an untapped opportunity for UK manufacturing. If just 10% of that were allocated to British-made PPE, uniforms, and essential goods, the impact would be transformative:

- Thousands of sustainable UK jobs

- Investment in new technologies, AI, and plant

- Ethical, transparent supply chains

- A revitalised, confident manufacturing base

Shockat Adam MP is now actively backing efforts to review public procurement policy, supporting a backbenchers debate led by Catherine West MP, which seeks to prioritise local social value over lowest unit cost.

The Leicester manufacturers spoke with one united voice, expressing deep pride in their work and strong support for an industry-wide shift in how manufacturing is valued and supported in the UK.

Action Points:

- ATMF to act as a coordinating body for distributing public contracts fairly among compliant UK factories.

- Engage further with MPs including David Lammy, Catherine West, and key stakeholders.

- Campaign publicly for a review of procurement practices, factoring in full UK economic impact, not just price.

- Highlight success stories from the ground to show Made in Britain works.

Shehzaad Valli from NVC International said: “It was an absolute pleasure having Shockat Adam join us and further strengthen our movement, his expertise & resources will prove to be groundbreaking in what we are trying to achieve, further proving the sector isn’t “flogging a dead horse” but a sleeping superpower that will be a key figure in the resurrection of the economy!”

Special thanks to:

- Shockat Adam MP for his time, insight, and clear understanding of the sector

- The factory owners and manufacturers who shared their experiences

- The incredible staff at FTA Leicester: Divya Kamath, Jo Bean, Puja Singh, and Sanna Bux — whose tireless efforts support the next generation of stitchers and makers

Leicester has it all for UK manufacturing: speed, skill, passion, and community. All it needs now is work.

The government, brands, and retailers must seize the moment and recognise the economic and ethical imperative of investing in Made in the UK starting with Leicester.