Fabric Treatment Innovations Transforming UK Fashion Production

04-12-2025

The UK fashion industry continues to evolve through remarkable technological discoveries, particularly in fabric treatments. These changes are altering production processes across Britain’s textile sector, offering manufacturers new ways to create distinctive designs while maintaining the quality craftsmanship for which British fashion is renowned.

As the fashion sector moves toward more localised production chains, these technological advances present a promising path for UK manufacturers looking to strengthen their position in the global market. The combination of traditional British textile skill with advanced treatment processes creates unique opportunities for brands dedicated to domestic manufacturing excellence.

Sustainable Fabric Treatments Reshaping UK Fashion Manufacturing

British textile manufacturers are adopting new sustainable fabric treatments that reduce environmental impact while supporting high-quality output. The momentum for these eco-friendly processes reflects increased consumer demand for responsible production.

Many mills and suppliers now choose biodegradable finishes and low-impact dyes as standard practice, drawing on best-practice roadmaps supported by WRAP and industry leaders. The precision of these treatments is similar to the accuracy required in other advanced technologies, such as specialist tattoo removal in London, where careful application ensures optimal results.

For example, WRAP’s case study database documents a Yorkshire woollen mill that achieved substantial water reduction using on-site filtration systems. London area suppliers have trialled enzymes in place of chemical fabric softeners, reducing pollution while meeting growing retailer demands for cleaner supply chain data.

(Image by Tima Miroshnichenko – pexels.com)

Water-Free Dyeing Technologies

Among the most progressive sustainable treatments in UK fashion manufacturing is the adoption of CO2-based dyeing processes. This technology, introduced by companies like DyeCoo, uses pressurised carbon dioxide instead of water to penetrate fibres with dye, eliminating water usage entirely.

The environmental benefits are considered significant. Traditional dyeing is known to use large amounts of water, with some processes generating considerable wastewater. CO2 dyeing requires no water and is believed to offer energy savings compared to conventional methods, supporting both environmental targets and high production standards.

Reports from industry bodies and companies trialling partial CO2 dyeing systems in the UK note marked water savings and more consistent colour results. Production times are often shorter compared with traditional dyeing, offering manufacturers both sustainability benefits and operational advantages.

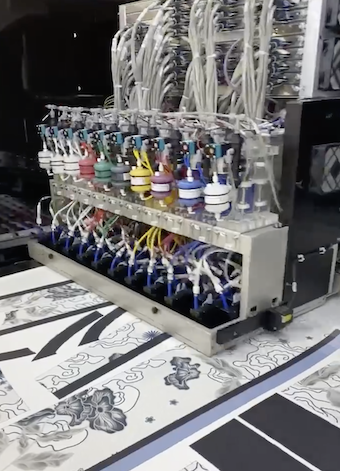

Digital Printing Advancements in UK Textile Production

Digital printing technology has transformed small-batch production across the UK textile industry. This technology reduces waste compared to traditional screen printing and is increasingly adopted by manufacturers seeking to lower their environmental impact while improving production flexibility.

Digital printing uses less water and produces fewer chemical byproducts than conventional methods. UK manufacturers like Fashion-Enter Ltd in London and the Textile Centre of Excellence in Huddersfield have adopted digital printing to enable on-demand production, allowing smaller brands to produce exactly what they need when they need it.

This shift helps address overstock issues that have traditionally troubled the fashion industry while supporting more sustainable business practices. The precision technology in fabric printing is similar to other precision treatments in various industries, offering manufacturers new capabilities for detailed designs.

(Image: Kornit Digital printing)

On-Demand Manufacturing Models

Digital printing has supported a major shift toward just-in-time production models in UK fashion manufacturing. London-based Unmade has introduced a system allowing brands to produce garments only after they’re ordered, reducing inventory waste and supporting more sustainable business models.

Similarly, Manchester’s Print on Demand has partnered with UK designers to create collections that are printed and constructed only when purchased. This model is reported to help reduce these brands’ carbon footprints while improving cash flow through eliminating the need to finance large inventory holdings.

The environmental advantages for UK manufacturers include reduced waste and potentially lower emissions. Reducing overproduction can help minimise unnecessary transportation and resource usage, helping brands match their environmental and business goals more effectively.

Laser Technology Transforming Fabric Finishing

Laser technology has created important advancements in UK fabric finishing. The adoption of laser systems is especially notable in denim processing and detailed pattern creation, where precision and efficiency are key for modern textile production.

These laser systems are replacing chemical-intensive processes, especially for denim distressing. Traditional stonewashing techniques are water-intensive and require harsh chemicals, while laser distressing requires no water and no chemicals, achieving more accurate and consistent results.

The precision of laser technology in fabric finishing offers manufacturers advantages in quality control and environmental performance. This technology allows for detailed customisation while reducing resource consumption throughout the production process.

(Selection of denim finishes presented at LaundRe)

Denim Innovation Through Laser Processing

The UK denim sector has particularly benefited from laser processing technology. Manufacturers using laser distressing systems have reported substantial reductions in water usage compared to traditional stonewashing, supporting sustainability goals while maintaining product quality.

These laser systems are also said to deliver energy savings. Industry reports indicate that laser processing can use less energy than conventional denim finishing methods, while producing more consistent results across production runs.

The accuracy of laser technology helps ensure that every garment in a production run has identical distressing patterns. This reduces the variation found in manual or chemical processes, becoming a strong selling point for brands that focus on quality.

Antimicrobial and Functional Fabric Treatments

The development of antimicrobial and functional fabric treatments marks a new direction in UK textile manufacturing. Functional fabrics are seeing increased demand, with antimicrobial treatments gaining traction as consumers seek longer-lasting, hygienic garments.

These treatments are intended to support longer garment use by reducing the need for frequent washing. Innovations in fabric care technology are helping to extend garment life and decrease environmental impact by minimising the frequency of laundering, which may help reduce their environmental footprint while maintaining hygiene standards.

Clear regulations around antimicrobial textile treatments are essential because they set out standards for product safety and offer reassurance for fashion manufacturers adopting new technologies. These guidelines help ensure consumer safety while supporting innovation in the textile sector.

Performance-Focused Treatments for Activewear

Treatments designed to improve performance have become central to the UK activewear sector’s competitive edge. Moisture-wicking technologies, developed at sites such as Dewhirst in Leicester, allow fabrics to transport sweat away from the skin, helping wearers stay dry during extended training.

This function matters because moisture retention in clothing can lead to discomfort, skin irritation, or chafing, especially during high-intensity activity. Fast evaporation supported by these treatments is considered important for wearer comfort and can help prolong the usability of activewear garments.

Temperature-regulating finishes are equally important. These help stabilise body temperature in a range of training environments. Leading UK sports brands including Sweaty Betty and Castore have incorporated these specialised fabric technologies in their locally manufactured lines.