Silver Birches at 50: A Label Company Rooted in the Made in Britain Revival

29-10-2025

Silver Birches began in October 1974 when Len Harris, aged 55, stepped away from his previous role in a large garment labelling company. Bound by a two-year non-compete agreement it was assumed he would most likely retire. However, he encouraged his eighteen-year-old son, Clive, to start something of his own; working from the family’s home in Chilwell printing labels in the garden shed and curing them in the kitchen oven. The house was named Silver Birches and the name ended up sticking. By the end of 1975 the business had moved into a small, rented workshop, and a year later, with Len free to join, The Silver Birches Label Co. Ltd. was officially incorporated.

(Len Harris – Labelling scheme 1973/74)

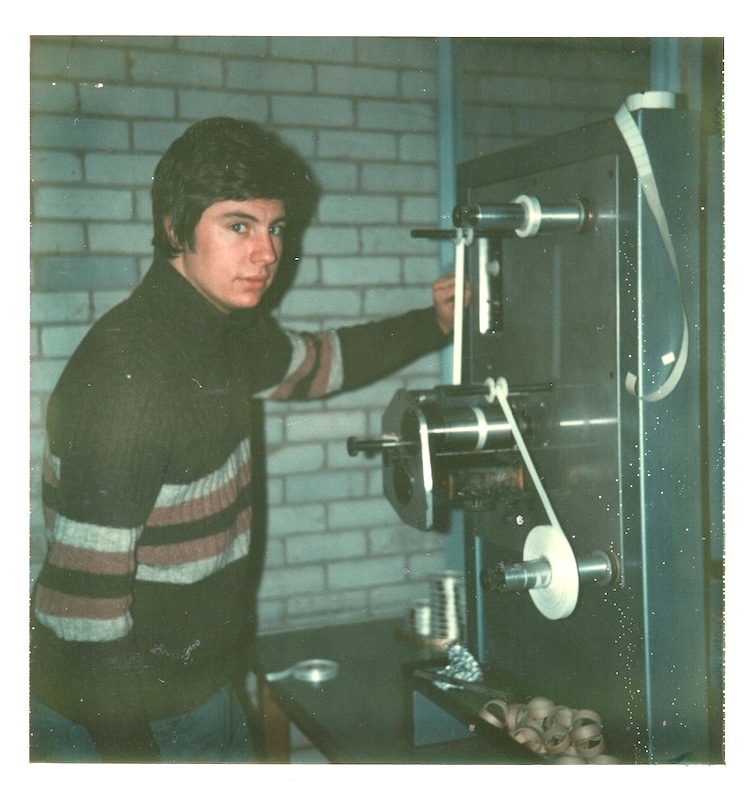

(Clive Harris and printing machine 1976)

(Silver Birches Attenborough premises 1982 – 1984)

From those makeshift beginnings, the company grew steadily. It purchased its own premises at Birch House in Attenborough, doubling turnover within two years and expanding its workforce. Through the 1980s and 1990s, production scaled to a two-shift, seven-day operation to meet increasing demand. As UK manufacturing shifted overseas, Silver Birches evolved with the times, establishing operations in Hong Kong to support global production and ensure customers received consistent quality and service wherever they operated.

(Silver Birches today)

(Silver Birches printing and cutting room)

Today, after five decades, the company has come full circle. Its renewed focus on UK manufacturing reflects a long-term belief that producing closer to home is both environmentally and economically more sustainable. Bringing more production back to Britain also strengthens local supply chains, supports domestic brands and preserves the craftsmanship and accountability that have defined Silver Birches from the start. As proud Made in Britain members, the company combines its British heritage with global reach and technical capability, proving that sustainable, high-quality labelling and packaging can be made responsibly in the UK.

(Silver Birches products: labels and packaging)

In recent years, Silver Birches has also diversified its product range beyond traditional labels and packaging to include promotional items, point-of-sale materials, retail and e-commerce packaging, stationery and general garment trims. The idea is to help brands simplify and strengthen their supply chains by managing a broader scope of sourcing, compliance and traceability through a single trusted partner. This joined-up approach allows customers to reduce complexity, improve efficiency and ensure every branded component meets the same standards of quality and responsibility.

Attention to detail remains at the centre of everything the business does. A label or a box is treated as part of a product’s story, to be crafted with the same care as the garment or item it accompanies. With facilities in the UK and the Far East, the company delivers sustainable short-run options as well as large-scale international manufacturing. That flexibility, along with a service-first ethos, has helped maintain long-term relationships across the fashion and retail sectors.

Sustainability underpins the company’s direction. Silver Birches holds ISO 14001 environmental certification, but its commitment goes further. By emphasising its commitment to more manufacturing in the UK, it reduces transport emissions, improves oversight and invests in local skills. Waste reduction is another priority: the company uses recycled and recyclable materials wherever possible and actively promotes re-use by offering surplus stock for re-sew and creative upcycling projects. Any high-quality material left on the shelf is seen as an opportunity for reinvention, not disposal.

As Extended Producer Responsibility (EPR) legislation approaches, Silver Birches is helping brands prepare for stricter environmental compliance. It provides material traceability and data transparency to ensure substrates and finishes meet recyclability and reporting standards. Localising production simplifies this process; shorter supply chains mean fewer intermediaries and clearer accountability. The company sees this shift as a positive step towards a more transparent and responsible fashion industry.

Looking ahead, Silver Birches continues to prioritise sustainability, circularity and UK production. Investment in digital proofing and sampling will help cut waste and speed up lead times, while research into alternative materials is ongoing. The business is also deepening collaboration with UK designers and brands, developing packaging and trims earlier in the creative process to deliver products that are locally made, environmentally conscious and built to last.

After fifty years, Silver Birches remains true to its founding principles; making quality products, supporting UK industry and finding better ways to work with the planet rather than against it.

To find out more about Silver Birches visit: https://www.silverbirches.com/